turbine flow meter working principle ppt

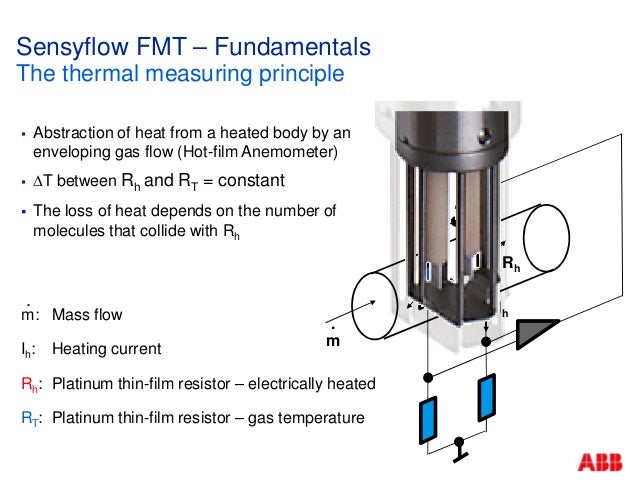

Platinum thin-film resistor electrically heated. The flow meter is characterized by simple structure high precision and easy installation and repair.

Ppt Turbine Flow Meter Powerpoint Presentation Free Download Id 2685380

The pulse rate is depended upon the flow rate.

. What is a turbine flow meter how turbine flow meter work parts of a turbine flow meter advantages and disadvantages of turbine flow meter. Orifice meter Venturi meter Rota meter Pitot tube. Flow meters are also known as Flow Gauges or flow measurement instruments.

Turbine Flow Meter Construction and Working Principle in Hindi Flow Measurement by Turbine Flow Meter in Instrumentation measurement system -Watch Electro. The rotor shaft spins on bearings. Electromagnetic Flow Meters simply known as mag flow meter is a volumetric flow meter which is ideally used for waste water applications and other applications that experience low pressure drop and with appropriate liquid conductivity required.

The delta or differential time is used to calculate the velocity of the liquid. When the fluid moves faster the rotor spins proportionally faster. Working Principal Turbine meters are inferential measurement devices that measure a flow rate indirectly by using the natural kinetic energy of the flow as it passes through the angled blades of the turbine rotor.

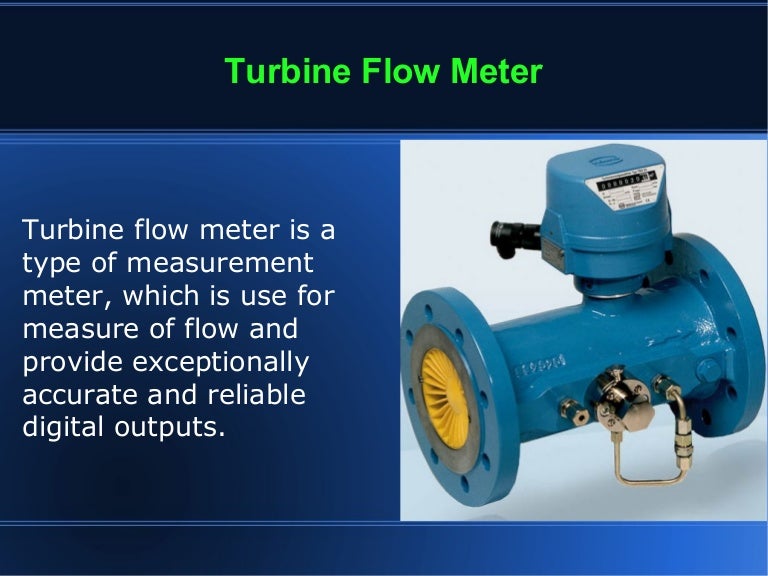

The turbine meter is an accurate and reliable flowmeter for both liquids and gases. A flow meter is a device that measures the flow rate of a fluid. How the Turbine Flow Meter Works.

A secondary rotation forms in the vortex core producing thread-like spirals. The most diverse substances are transported and distributed in piping system in every single day they may include solvents chemicals oilgas drinking water fruit juices slurries etc The fluid flowing through. Turbine flow meter consists of turbine flow sensor and display instrument and it is made by us using foreign state-of-the-art technologies which is an ideal gauge for measuring of liquid flow.

M Ih Rh RT Abstraction of heat from a heated body by an enveloping gas flow Hot-film Anemometer T between Rh and RT constant The loss of heat depends on the number of molecules that collide with Rh m. The angular velocity of the rotor results in the generation of. The flow meter is highly accurate and often used for testing the performance of pumps engines valves and other flow meters.

Principle of Operation Turbine Flow Meters. A flow meter or flow sensor is an instrument used to measure linear nonlinear mass or volumetric flow rate of a liquid or a gas. The objective of our presentation is comparisons of different flow measuring devices.

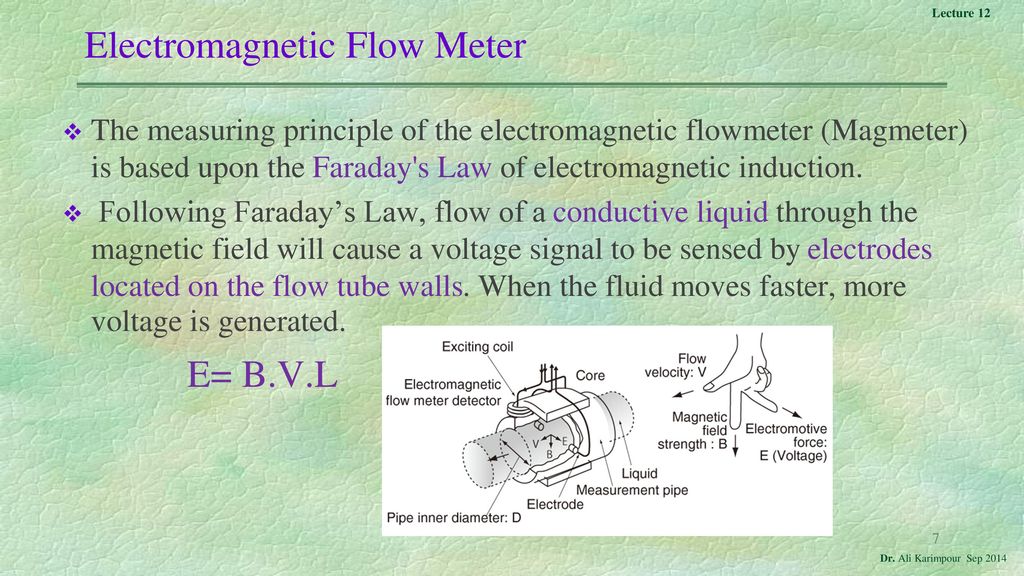

So how does a turbine flow meter work. Working Principle The operation of a Electromagnetic flow meter or magmeter is based upon Faradays Law which states that. Minimum length of straight pipe is required upstream and downstream of the vortex meter.

Swirl Flow meters Principle. Vortex Flow Meter Limitations. A turbine flow meter is constructed with rotor and blades that use the mechanical energy of the fluid to rotate the rotor in the flow stream.

Electromagnetic Flow Meters Working Principle. The rotor shaft spins on bearings. Flow meters are flow measuring instruments used to measure the linear nonlinear mass or volumetric flow rate of a gas or a liquid.

When the fluid moves faster the rotor spins proportionally faster. Accurate flow measurements of gases and liquids are required for the. Blades on the rotor are angled to transform energy from the flow stream into rotational energy.

The operation of the International Turbine Meter is based on the measurement of the. When choosing flowmeters one should consider such intangible factors as familiarity of plant personnel their experience with calibration and maintenance spare parts availability and mean time between failure history etc at the. The RS485 communications standard is used by Measurement Systems Pickoff Sensor based data acquisition modules and many industrial control devices.

The design of a turbine flowmeter means there is very little drop in pressure and it is for this reason that they are regarded as one of the most accurate measurement tools. Turbine Flow Meter is a volumetric measuring turbine type. Lets explain how a turbine flow meter works in detail.

What is the principle of turbine flow meter and how does it work. Turbine flow meter is used for translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user readable rate of flow. This device would convert the mechanical action of the rotating turbine in the.

It consists of a multi-bladed rotor mounted at right angles to the flow and suspended in the fluid stream on a free-running bearing. The frequency of this secondary rotation is linearly proportional to the flow rate over a wide Reynolds Number range. The principle behind these meters is that an ultrasonic signal is transmitted downstream or in the direction of the flow while another signal is transmitted upstream.

The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate. The faster you pedal the faster you move. The key components in a turbine flowmeter is the tube or body of the unit a rotor and support spindle and a magnetic pickup which measures the speed of the liquid.

The product may be used in a wide range of industries including oil industry chemical. The turbine is rotated by the flowing fluid these rotating blades would create pulses that would be recorded and the flow rate is determined by this. That velocity is then used to calculate the volumetric flow through the pipe.

Blades on the rotor are angled to transform energy from the flow stream into rotational energy. Not suitable for very low flow rates. A turbine-shaped inlet section forces the axial flow entering the flow meter into a rotational movement.

Such method is very similar to cycling. Sensyflow FMT Fundamentals The thermal measuring principle. The device doesnt have any moving parts and cannot work with hydrocarbons and.

The fundamental design goal of a turbine flow meter is to make the turbine element as free-spinning as possible so no torque will be required to sustain the turbines rotation. Vortex Flow Meter Applications. Flow of liquid or gas acts as a driving force and turbine rotor as the wheels.

Our Turbine Flow Meters are easy to use and work with utmost precision. If this goal is achieved the turbine blades will achieve a rotating tip velocity directly proportional to the linear velocity of the fluid whether that fluid is a gas or a liquid. The voltage induced across a conductor as it moves at right angles through the magnetic field is proportional to the velocity of that conductor 6.

Vortex flow meters are suitable for a variety of applications and industries but work best with clean low-viscosity medium to high speed fluids. This principle is based on tracking multi bladed rotor rotation speed. A vortex core forms in the centre of the primary rotation.

Thermal Mass Flowmeter Abb N V

Working Principle Of Turbine Flow Meter

Ppt Beneficial Flow Meters With Sincere Instruments Powerpoint Presentation Id 7968507

Working Principle Of Turbine Flow Meter

Ppt Introduction To Flow Meters Powerpoint Presentation Free Download Id 2327953

Electromagnetic Flow Meters Working Principle Instrumentationtools

Turbine Flow Meter Working Principle Instrumentationtools

Flow Rate Measurement Class Ppt Video Online Download

Swirl Flow Meters Working Principle Instrumentationtools

Lecture 3 Flow Level Temperature And Light Measurement Ppt Video Online Download

Turbine Flow Meter Principle Ppt Archives Inst Tools

Module V Ppt Video Online Download

Turbine Flow Meter Principle Advantages Disadvantages

Introduction To Flow Meters Ppt Video Online Download

Electromagnetic Flow Meters Ppt Video Online Download

Module V Ppt Video Online Download

Working Principle Of Turbine Flow Meter

Measuring Or Working Principle Of Turbine Flow Meter Youtube